Recently Power Technology Services were awarded a large project in Columbia this project involved design and manufacture of high pressure Class 900 Hot Tapping and Line Stopping equipment including Line Stop valves, Line Stop Heads, Line Stop Cylinders, Line Stop Housings, all to Class 900 RTJ with a working pressure of 2220 PSI.

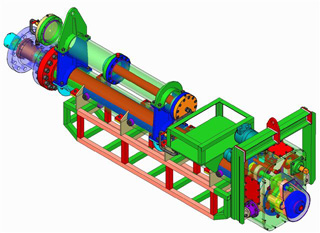

Our challenge was to design the Tapping machine to work at these pressures. With such a short delivery time, of just 12 weeks, Power engineered a new 3680 (Max 36 inch Taps with a travel of 80 inches) High Pressure Tapping machine to work with an external hydraulic accumulator (note this accumulator is not of a bag design) this allowed us to advance and retract the cutters and completion plugs without any difficultly into the pipeline. Operating pressure on site at the time was 1280 PSI (87 Bar) The machine capabilities are: 2220 PSI (151 Bar) working, tested to 3322 PSI (226 Bar)

Our challenge was to design the Tapping machine to work at these pressures. With such a short delivery time, of just 12 weeks, Power engineered a new 3680 (Max 36 inch Taps with a travel of 80 inches) High Pressure Tapping machine to work with an external hydraulic accumulator (note this accumulator is not of a bag design) this allowed us to advance and retract the cutters and completion plugs without any difficultly into the pipeline. Operating pressure on site at the time was 1280 PSI (87 Bar) The machine capabilities are: 2220 PSI (151 Bar) working, tested to 3322 PSI (226 Bar)

Kevin Dobbs Operations Manager thanks his design team in achieving a further milestone within the business and briefly explains how the machine operates:

Once the pilot drill penetrates the pipeline, the pipeline pressure flows into the cutter adaptor and gradually increases, once the pressure is reached the control valve from the Tapping machine end noggin is opened, the pressure and product enters the external accumulator which then pushes the piston forward, the drilling machine is manufactured fully charged with hydraulic oil and when the piston goes forward it gives a positive pressure in the Tapping machine, this positive pressure allows the operators to advance and retract the boring bar without being affected by the pipeline pressures.

Operator Mr Gez Thompson completed the two position 24” Line Stop with bypass without any interruptions and commented:

“The machine was of superior design and it made my life so easy doing the Hot Taps and setting the completion plugs at such high pressure.”