"When you are under pressure to install a valve in an operating line call Power Technology Services"

- Can be used in lines with up to 150psi ambient pressure

- Installed valve has the same number of turns as any other comparable valve in your system

- 4", 6" or 8" installations in cast iron, steel, ductile iron, A/C or PVC C-900 pipe

- Uses modern compression gate technology

Material Specifications >>>

Some Advantages of the QuikValve >>>

Frequently Asked Questions >>>

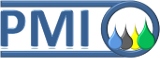

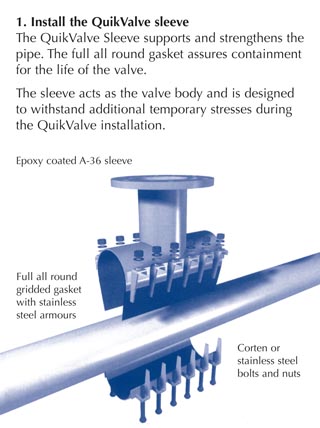

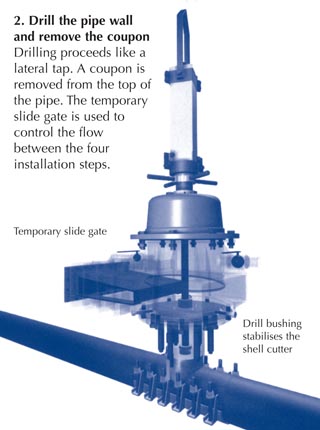

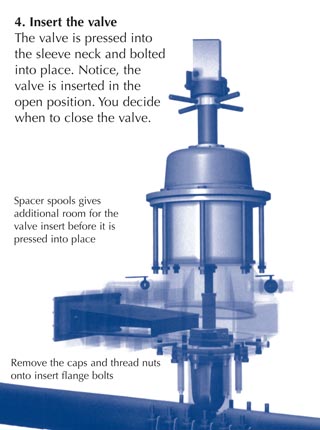

Installing the QuikValve is as easy as 1.2.3.4

Material Specifications

QuikValve Tapping Sleeve

General: The sleeve is fabricated to assure a 360 degree seal around the pipe under working pressures up to 150 psi. (Test pressure: 225 psi.) It is designed to accommodate the equipment and fixtures necessary to drill and ream the pipe and install the QuikValve insertion valve without any interruption in service.

Materials: The sleeve is made of ASTM A-36 steel, expoxy coated to 10-12 mils.

Flange: A special flange is used that mates with the QuikValve installation equipment and insertion valve.

Neck: The neck is manufactured to precision tolerances that assures proper alignment, support, and sealing of the Quikvalve insert.

Bolts and Nuts: High strength low alloy steel (Corten) bolts and nuts meeting AWWA standard C-111. Type 304 stainless steel bolts with SDC nuts are optional.

Gaskets: All gaskets are made of Styrene Butadiene Rubber (SBR) compounded for potable water service in accordance with ASTM D2000 3 BA715. The gaskets provide a positive 360 degree seal on the pipe and assure a tight, durable, and resilient seal at the pipe sleeve – valve insert junction. Other seals on request.

Coating: The sleeve is lined and coated with fusion bonded epoxy. Epoxy meets the requirements of AWWA-C213.

Armours: Heavy gauge type 304 stainless steel armour plates are used to bridge the gap between the sleeve halves.

Lugs: Lugs on the sleeve are configured to properly align the sleeve halves during installation, provide a bolting surface, and assure a 360 degree seal. The lugs are designed to prevent excessive stress on the pipe, and minimize distortion of soft (PVC) pipe.

QuikValve Valve Assembly

General: The valve assembly, when installed in a QuikValve sleeve, performs as a control device with an effective shutoff of the flow. The valve is installed in the open position, under pressure without any interruption of service. The QuikValve gives a full unobstructed full flow waterway after installation.

Insert: The insert consists of a ductile iron casting coated with SBR rubber compounded for water service with a durometer of 55 Shore A. The insert seals on the inside diameter of the QuikValve sleeve neck and the lower half of the water main. Other seals on request.

Valve Stem: The stem and nut assembly are in accordance with AWWA C-500-80, section 3.12.

Flange: A special flange, made of ASTM A-36 steel is used that holds the valve assembly together and acts to seal against the valve sleeve flange.

Gasket: The valve flange gasket is made of SBR rubber, compounded for water service in accordance with ASTM D2000 3 BA715, with a durometer of 70 Shore A. The gasket acts as the sealing interface between the valve flange and the sleeve flange. Other seals on request.

Bolts and Nuts: Grade 3 Alloy steel, zinc plated for corrosion protection. Type 304 stainless steel bolts, nuts and washers are optional.

Some Advantages of the QuikValve

The valve is inserted in the open position, so no matter how the water flow is configured, there is no loss of pressure.

The process is quick, usually much faster than alternative methods of line stopping or cut-ins. The average installation time is between two and three hours.

There is only one cut in the main, and the main is never severed. The pipe retains its structural integrity just as it would with a size on size lateral tap.

The insert uses a standard valve stem and nut. Any QuikValve installation will have the same number of turns to open and close as any valve in the system.

Should the need arise, the QuikValve insert is replaceable under pressure.

The insert uses the newest technology, the rubber coated wedge. This gives the QuikValve good sealing characteristics with an installation pressure rating of up to 150 psi.

Due to the small envelope of the installed QuikValve, it has been installed in places where other pipelines and conduits precluded a valve cut-in.

The QuikValve insertion machine doubles as a 3” through 12” lateral tapping machine. With 27” of travel, the equipment easily handles a size on size 12” tap. Incidentally, the manual feed on the machine has proved to give the operator a real feel for the cut, allowing him to stop if trouble arises before damage to the main occurs.

The QuikValve gives a new method to easily isolate pipelines.

Frequently Asked Questions

Q. Does the valve have the same number of turns as a standard valve?

A. Yes, and the same height.

Q. What are the differences between the QuikValve sleeve and a standard fabricated tapping sleeve?

A. There are three main differences:

1. The QuikValve sleeve has a machined neck due to the tolerances required to allow the insert to seal.

2. The QuikValve sleeve uses an all-around full seal gasket and armours instead of just a neck ring.

3. The QuikValve sleeve has a narrow range, just +0.10, again to optimise sealing characteristics.

Q. Why do you use an all around gasket instead of a neck ring on the QuikValve sleeve?

A. We felt that sealing all the way around the pipe added significantly to the stability of the product. This is the design we have always used in our clamp products. The all around seal gives an increased safety margin against any leaking around the edges of the QuikValve sleeve, supports the pipe, and applies a more even pressure gradient to the outside diameter of the pipe wall.

Q. What is the valve insert made of?

A. The insert is a ductile iron cast plug that is encased with 55 durometer SBR rubber. The rubber is bonded to the casting during the rubber moulding process.

Q. Does this valve meet the AWWA valve specification?

A. No, there is no AWWA specification that covers the QuikValve. If it ever does have an AWWA specification, it will be under a new category, separate from the standard cast valve specifications. The QuikValve’s operating mechanism, the stem and nut, are standard and meet AWWA requirements.

Q. Will the QuikValve always give a 100% seal?

A. We don’t guarantee a 100% seal. Our installations thus far have given a 100% seal. We do guarantee a seal that will allow work to be completed on your line.

Q. What is the warranty period on the QuikValve?

A. One year.